Reducing food-borne bacterial infections must be team effort

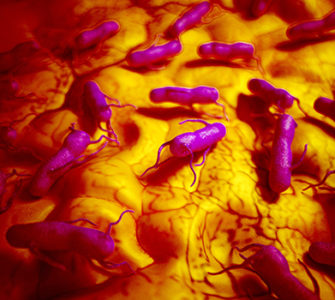

Increased pressure to reduce bacterial food-borne infections in consumers is affecting poultry production from start to finish, panelists reported at a food safety roundtable, “Lightening the Load: Teaming live production with processing to meet USDA’s new limits for foodborne pathogens.”

Calhoun

Traditionally, the processing plant has borne the brunt of managing food-borne pathogens, particularly Salmonella and Campylobacter. Over the past couple years, however, “The mentality seems to be different on the live side, which has really stepped up its game,” said Shane Calhoun, formerly vice president of quality assurance for OK Foods and now food safety account manager for Zoetis.

There’s more communication and teamwork between processing and live production, largely due to USDA’s presence in plants. “The processing plant knows more now about what’s coming in…and about things like proper feed withdrawal — certain aspects I never dealt with in quality assurance 2 years ago,” Calhoun added.

A similar trend is evident at Sanderson Farms, said Marty Ewing, DVM, director of technical services for the poultry company.

Ewing

“We try to anticipate the quality of the poultry coming into the processing plant and maybe we can correlate that to the pathogen load,” she explained. “Surely, a good, healthy flock is going to have less microbial contamination than a sick one.”

Nevertheless, there are always surprises, so it must be assumed all flocks are Salmonella-positive and should be treated alike, Ewing said. “Heaven forbid if an outbreak occurred and could be traced back to that day’s production when one flock was processed differently from another. There’s liability to consider.”

Performance standards

Several panelists expressed concern about the government’s new, higher performance standards for Salmonella and Campylobacter and the ability of the poultry industry to further reduce the pathogen prevalence.

Singer

Randall Singer, DVM, MPVM, PhD, University of Minnesota, said, there’s “no way” a single sample per day or a single sample per week can predict a spike in the foodborne pathogen load. For this reason, he encourages poultry producers to have a good processing plant monitoring system.

“This is where I would encourage [poultry] companies to focus — understanding the risk in the plant…Nobody should be relying on the performance standards,” Singer added.

Ewing asked the panel whether USDA has a realistic expectation of what the poultry industry can do with managing Salmonella in a raw product.

“Salmonella is ubiquitous in our system [of live production], but USDA does not have the intimate knowledge you do of what happens in a plant and what you can do, realistically, to control Salmonella,” said Douglas Fulnechek, DVM, former supervisory veterinary medical officer, USDA’s Food Safety and Inspection Service (FSIS), and now a technical service veterinarian for Zoetis.

Smith

John Smith, DVM, ACPV, a consulting poultry veterinarian for Alectryon LLC, Baldwin, Georgia and formerly with Fieldale Farms, said that in his experience, processing plants meet USDA standards well. There are probably ways to make further improvements, but “I don’t know that we can ratchet up our in-plant control procedures enough to meet a more stringent standard. Live production may need to play a bigger role,”

The government is imposing a disservice on the poultry industry by leading consumers to believe all raw chicken is safe, insisted Eric Willinghan, DVM, a veterinarian for of Winfield Veterinary Consulting, Florida. It would be better to further educate consumers about how to properly handle and cook chicken, he added.

Willinghan

While he supports efforts to reduce food-borne pathogens in live production, the veterinarian cautioned that it could invite more government standards. “If we start claiming on-farm interventions…we could end up having to let USDA validate them, and that’s opening ourselves up to more USDA inspection, possibly at the farm,” said Willinghan, who also serves as the American Association of Avian Pathologists’ representative to the AVMA Food Safety Advisory Committee

Salmonella in breeders

For breeders, the panelists agreed vaccination is useful for managing Salmonella but they emphasized that vaccination alone would not suffice.

Fulnechek said that of all the tools he’s looked at over more than 20 years, vaccinating breeders for Salmonella has consistently yielded benefits. “Breeder vaccination is probably one of my first choices or lines of defense,” he said.

Smith added, “We know that vaccination works” and said it was a “tremendous aid,” but he emphasized that it was not a silver bullet and that no one knows which program offers the best protection.

He cited experience in Georgia, where most breeders are vaccinated against Salmonella but the vaccine protocols vary widely. In addition, there are multiple serotypes, so the challenge is choosing the correct ones.

“Most of us try to target the big food-safety ones — the Heidelbergs, the Typhimuriums and maybe Enteritidis. But we see a number of other serotypes, too, and they’re prone to change over time. That’s an issue,” as well as vaccine administration, Smith said. “You’ve got to get these vaccines into the chickens for them to work.”

O’Connor

Robert O’Connor, senior vice president of technical services, Foster Farms, called vaccination a “partial” insurance policy. “Folks outside the industry need to understand that. It’s overly optimistic to put all your weight on vaccination for solving the Salmonella issue.”

Willinghan considers bacteria control a numbers game in poultry production. “You can’t vaccinate your way out of it because you’re never going to protect 100% of the birds,” he said. For that reason, he recommends using two killed vaccines versus mass-administered live vaccines for Salmonella so he knows humans are vaccinating each bird and more birds are likely to be vaccinated.

He and other panelists pointed out that any vaccine has a threshold and can be overwhelmed by Salmonella in the environment.

Hatchery procedures

Smith emphasized the importance of good hatchery sanitation, particularly regarding egg nests and procedures for egg gathering and grading. He suggested preventing eggs from sweating and also keeping egg coolers clean. Rodents also need to be kept out.

“You’ve just got to get serious and pay attention to details. I don’t know of any amazing product or procedure you can apply,” he said.

Keck

Panel moderator Lloyd Keck, DVM, senior technical service veterinarian, Zoetis, noted that some producers have removed gentamicin from the hatchery. He asked if it’s having an impact on the levels of Salmonella or Campylobacter.

Intuitively, it would seem eliminating antibiotics from the hatchery would increase Salmonella shedding and some surveys indicate organic and free-range poultry are as heavily or more heavily contaminated than chicken raised with antibiotics, Smith said.

However, there’s also evidence that Salmonella isolated from organic poultry and poultry raised under the “no antibiotics ever” label have less drug resistance.

“So, there might be a trade-off — increased shed but less antibiotic resistance — but we don’t really know,” Smith added.

Singer said his concern is not necessarily increased shedding, but a shift in the dominant Salmonella serotypes and strains.

O’Connor reported that Foster Farms saw a 0.5% increase in first-week mortality after removing gentamicin from the hatchery but there wasn’t a difference in drag-swab numbers for Salmonella. Using hydrogen peroxide in a timed aerosol in hatchers has proved to be a very effective intervention.

Sanderson Farms decided against discontinuing gentamicin use, Ewing said. A single dose has been shown to improve livability by at least 50% during the first week of life, she said. “That means half the number of chicks die from bacterial infection…how much selection for resistance can happen with a one-time single dose?”

Pathogen management in broilers

When asked if the trend toward antibiotic-free production is affecting the food-borne pathogen prevalence in broilers, panelists said there’s no good answer.

“I honestly don’t know,” said Smith, who has extensive experience with antibiotic-free production from his years at Fieldale Farms. “I think you could argue there’s some evidence these regressive techniques — or as a good colleague says, ‘raised without modern technology’ — is not helpful in regard to food safety.”

Singer said if an antibiotic is used, there’s the risk some bacteria such as Salmonella or Campylobacter could become more resistant, which would lead to more-resistant infections and potentially higher morbidity in people. “But there’s also the chance that by maintaining animal health, reducing subclinical illness and producing more homogeneity in bird size, you could potentially reduce product contamination and human illnesses,” he reasoned.

Hofacre

“At the end of the day, in my opinion, it’s always better to prevent infections. One way to reduce foodborne pathogen levels in the plant is to reduce subclinical illness and overall disease in live poultry.”

Charles Hofacre, now a consulting veterinarian for Southern Poultry Research Group, Athens, Georgia, and former professor at the University of Georgia, also said there’s no black or white answer as to whether antibiotic-free production means a greater risk for the consumer.

Nevertheless, he echoed the point that healthier flocks are probably less likely to harbor food-borne pathogens. Unhealthy birds, he added, are going to be less uniform in size and will have more nicked intestines and fecal contamination, which can result in a greater opportunity for Salmonella or Campylobacter to be on the carcass.

Biosecurity and farm hygiene

Biosecurity and farm hygiene, panelists said, are important not only for reducing food-borne pathogens, but for maintaining a company’s reputation.

Willinghan considers every farm a food-producing facility. “If the farm has trash around, no bathroom and no place with hot water to wash hands, I have to ask if it’s a place I’d want to eat. That’s the biosecurity metric that I use.”

For his clients, he’s successfully managed to eliminate the bottom, dirtiest facilities. “I tell [poultry companies], ‘that’s the farm that’s going to cause your name to be in headlines. It’s not going to be that farmer’s name. It’s going to be your corporation’s name’.”

“That’s an important point,” Singer added. “If there’s a lesson to be taken from the Danish experience [eliminating or minimizing Salmonella]…Well, they got rid of the worst producers” and were able to increase production even after eliminating in-feed antibiotic growth promoters.

O’Connor said when Foster Farms had a pullet house positive for a serotype of Salmonella that posed a food-borne threat, they followed a Danish-type model. “We isolated every single house on that farm and initiated strict biosecurity measures, and that serotype never left that breeder house.”

Hofacre emphasized the importance of individualizing biosecurity plans. For instance, some farms may have a greater beetle population that needs remedied while on other farms, rodents might be the primary problem. Sometimes, soil is an issue because certain Salmonella types live in soil and, in the US, poultry house floors are dirt, not concrete. Water disinfection for broilers is important and so are general biosecurity measures such as care when moving equipment from farm to farm, he said.

Feed and litter contamination

Feed can be a source of Salmonella, even though feed that’s extruded and pelletized should hit a temperature high enough to kill the pathogen, Ewing said The problem is keeping feed free of recontamination once it’s in the truck or on the farm.

To sample feed for Salmonella, O’Connor recommended sampling feed-mill dust. Regularly take a few dust samples from the top, middle, bottom — all throughout the feed mill — and it’s a pretty good indicator of what Salmonellas have come through the mill.

Regarding litter management, Ewing said new litter isn’t necessarily an advantage for reducing Salmonella because it often has a higher moisture level. That can result in more problems with Salmonella. Cycling and building litter up and as in-house composting may be helpful.

O’Connor said after a Salmonella outbreak involving broiler houses with Salmonella Heidelberg in litter, they cleaned houses to the ground and fumigated them with formaldehyde. The decrease in Salmonella in subsequent flocks at processing was “amazing.”

This type of “nuclear” cleanout is warranted and worthwhile for a pathogen like S. Heidelberg, he added, but would not be recommended for serotypes that aren’t pathogenic to humans such as S. Kentucky.

“You have to reach some sort of compromise from a business standpoint when it comes to the countless (~2,500) serotypes of Salmonella. How much are you going to push your economic envelope on interventions?” he explained.

“If my goal is to minimize risk, [I’m] always weighing decisions…In the case of litter, you compost and windrow and use litter amendments to try and kill/reduce the numbers of bacteria…You top-dress old litter with new litter to ‘dilute’ the numbers of bacteria or viruses in the litter that a new flock will use.”

Hofacre noted if there’s pathogenic Salmonella in litter, like S. Enteritidis, then yes, maybe that litter needs to be removed. “But if we keep it out, it doesn’t much matter if it’s built-up litter or not.”

Alternative products

Panelists were doubtful that alternatives such as competitive-exclusion products, essential oils, prebiotics and probiotics could make much of a dent in Salmonella on broiler farms.

“I’m highly skeptical of those products,” Smith said. “In antibiotic-free production, there’s not one alternative product that we have used consistently, mostly because they’ve been so inconsistent.” There’s evidence competitive exclusion and live vaccines help in broilers but in his opinion, they’re not as effective as breeder vaccination.

Ewing, O’Connor and Willinghan also reported inconsistent results with alternative products.

Campylobacter

Keck, the moderator, said although there are highly effective disinfectants that can be used during processing, there are no commercial vaccines to reduce Campylobacter. He asked what can be done during live production to better control this pathogen.

Probably not much, according to Hofacre. “What we know about the epidemiology of Salmonella in the chicken would fill this room. What we know about it for Campylobacter wouldn’t fill [a] water glass.

On the live side, it’s unknown why Campylobacter often can’t be detected until the birds are 14 to 21 days of age or why it escalates so that birds are shedding unbelievably high levels at 35 or 45 days of age in one flock while in another flock they may all be zero. It’s also unknown if Salmonella control measures will be effective against Campylobacter.

Singer said, “I could suggest two things. First, raise a bigger bird. Older birds seem to have less Campylobacter. Second, move to Minnesota. For some reason, our cold winters seem to knock Campylobacter down to nil.”

O’Connor said he knew of no validated intervention recommended for managing Campylobacter on the live side and agreed with Singer about bird size. “Most people in the industry who ask me about Campylobacter and are having problems with it are talking about a smaller, 4.5-pound bird, not an 8-pound bird.”

Sleepless nights

Keck concluded the roundtable by asking panelists what keeps them up at night.

“I don’t see how our [poultry company] CEOs sleep…” Smith said. “If left unchecked, any one of these organisms could destroy a poultry company.”

Singer reiterated his concern about whether risk models and performance standards developed by FSIS could actually predict anything related to public health. “In the end, it’s up to the [poultry] companies to do it themselves…” he added.

Ewing said because there are many sources for Salmonella other than chicken — fruits, vegetables and even flour — she believes the epidemiology is not thought out. “In other words, you can have a break, and because a Salmonella looks like a strain that had been isolated at a certain plant, even years ago, it could incriminate a facility. I’m worried about [poultry companies] being falsely accused while the true source of the outbreak is not identified.”

Fulnechek summed up everyone’s concern, underscoring the enormous burden on the poultry industry: “If we don’t all do our job, somebody could die. Salmonella, Listeria, E. coli — all those organisms are just waiting for a break in our defenses…”

For more information on the roundtable, ““Lightening the Load: Teaming live production with processing to meet USDA’s new limits for foodborne pathogens,” and a free copy of the roundtable proceedings booklet, click here.

Posted on July 25, 2017