New coccidiosis-management initiative aims to reduce losses

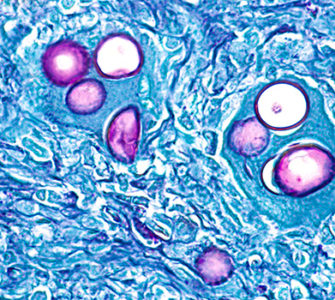

Targeting the global poultry industry’s more than $3 billion in annual losses to coccidiosis, Zoetis Inc. today introduced Rotecc™ Coccidiosis Management, a new, science-based initiative to help poultry producers worldwide develop more strategic, cost-effective and sustainable programs for battling the costly parasitic disease.

“Overall, the poultry industry has done a commendable job managing coccidiosis. But clearly, when you look at billions of dollars in losses associated with the disease, there is still lots of room for improvement,” Mark LaVorgna, PhD, a nutritionist and global technical services director for the company, said at a news conference in Atlanta before the 2014 International Production & Processing Expo.

“With Rotecc, we’re drawing on decades of published research, field and pen trials and our own experience managing coccidiosis in more than 60 countries to help close that gap. We are doing this not just with our own products but with all field-demonstrated anticoccidial tools available in the animal health industry.”

Rotecc begins with a consultation by a Zoetis representative, who reviews a poultry operation’s past and current programs, necropsy data and results from anticoccidial sensitivity testing, as well as seasonal preferences for product usage, production goals and management practices. Other variables such as feed costs and meat prices also are considered.

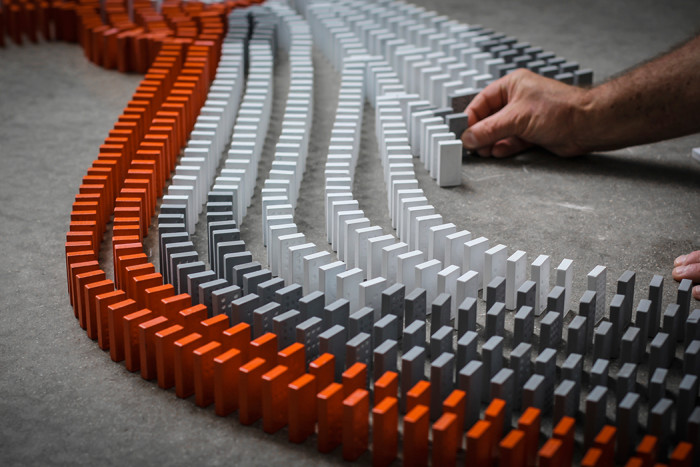

Rotecc is built on best practices widely accepted by the poultry science community for coccidiosis management. Specifically, this includes not using the same in-feed anticoccidial for too long, rotating among products from different classes, resting each product and using a synthetic anticoccidial once yearly to clean up lingering coccidia and help reduce infection pressure.

Don Waldrip, DVM, senior technical services veterinarian for the company, with years of production experience, said poultry producers would benefit from thinking longer term — perhaps even 24 months ahead — when developing their coccidiosis-management programs.

“The more you plan ahead, the more rotation options you’ll have available for effective coccidiosis management,” Waldrip said. “That’s important because it takes time to initiate effective rotation programs that will provide ample rest periods for each class of in-feed product.”

Waldrip acknowledged that rotating anticoccidials was standard practice at commercial poultry farms. “But sometimes,” he added, “traditional thinking, old habits, cost considerations and the pressures to achieve optimal short-term performance stand in the way of developing a longer term, sustainable strategy. Rotecc aims to put producers on the right track and, more importantly, keep them there.”

Vaccination is also part of the Rotecc strategy and can play an important role in coccidiosis management, depending on individual producer needs. It gives in-feed anticoccidials a rest and seeds poultry houses with coccidia that are still sensitive to the in-feed products, which restores their efficacy, Waldrip explained.

To support Rotecc, Zoetis is developing several digital tools to help producers and veterinarians tailor a long-term program to suit their individual needs. These include the Rotecc™ Program Advisor, an iPad app that initially will be available in the US, and a Rotecc™ Calculator, which will run on the iPad and Windows operating systems. It will be used to help determine the most cost-effective anticoccidials for each producer’s rotation plan while adhering to best practices for rotation.

Greg Mathis, PhD, president and owner of Southern Poultry Research, Athens, Ga., and a globally recognized expert on coccidiosis, expressed enthusiasm for the Rotecc initiative.

“When was the last time the world’s poultry industry got a new anticoccidial — 15 or 20 years ago?” he asked, rhetorically. “We still have good tools available, but we need to do whatever we can to preserve their effectiveness and optimize their performance. Planning ahead and thinking about your program 12, 18 and even 24 months from now is a huge step in the right direction.”

Mathis also urged producers to “rotate smarter” and learn the differences between anticoccidials. “I see producers rotating from, say, monensin or salinomycin to narasin, but all they’re doing is rotating from one monovalent ionophore to another,” he said. “They’d be better off rotating to a divalent ionophore, a chemical or even a vaccine,” he said.

For more information about Rotecc, producers and veterinarians should contact their local Zoetis representative or visit Zoetis.com/poultry.

Posted on October 14, 2015