Life without antibiotics: Field lessons learned the hard way

Producers

need to think long and hard before jumping into “no antibiotics ever” (NAE)

poultry production, Tim Cummings, DVM, technical service veterinarian for

Zoetis, told Poultry Health Today.

Transitioning

from conventional to NAE production requires a tremendous amount of planning as

well as management changes at all levels of production, cautioned Cummings, who

has been in close communication with a number of producers making the change.

A successful

NAE program starts with breeder pullets. The vaccination program needs to be as

strong as possible to pass adequate immunity on to broiler progeny. This means NAE

producers will probably have to spend more on vaccines, and they must take

great care to make sure vaccines are administered correctly, Cummings said.

There’s always

a small percentage of eggs that breeders lay on the floor, and they always have

a higher bacterial load than eggs laid in nests. Cummings advised they be

discarded, not cleaned and sent to the hatchery.

Hatchery improvements

Sanitation at

hatcheries in NAE systems must improve significantly, Cummings continued. When

hatcheries stop using gentamycin, they soon discover the antibiotic was masking

sanitation deficiencies that lead to increased mortality in week-old chicks.

Attention to

the cleanliness of hatchery ventilation systems is an important but easily overlooked

chore, he noted. It requires more than just adding a couple of ounces of

disinfectant to the ventilation system. Equipment must be checked to see if it’s

dirty and be properly cleaned and disinfected.

Water sources

for hatcheries in NAE systems likewise need to be checked for cleanliness; that

includes culturing at different points throughout the hatchery to test for

contamination. Don’t assume the water is clean, Cummings warned.

A big deficiency

he’s noted in NAE systems is inadequate washing of tray and chick boxes. Too

often, there’s still organic material left. It’s vitally important to monitor

and maintain temperature and disinfectant levels in washers, and in some of the

older hatcheries, the washers need to be replaced, he said.

Detailed broiler management

On the

broiler side, Cummings said husbandry during the first 2 to 4 weeks of life is

critically important to prevent necrotic enteritis (NE), which has been one of

the biggest problems NAE systems face, but producers are learning how to

prevent this costly disease.

Keys to preventing

NE include dry litter, good ventilation, reduced stocking density, increased

downtime between flocks — and quality feed.

“You really

need to spend more money and get good-quality ingredients in the feed,” he

said. Eliminate ingredients that might make birds more susceptible to NE, like meat

and bone meal. Constant feed intake is also key since running out of feed appears

to increase the risk for NE.

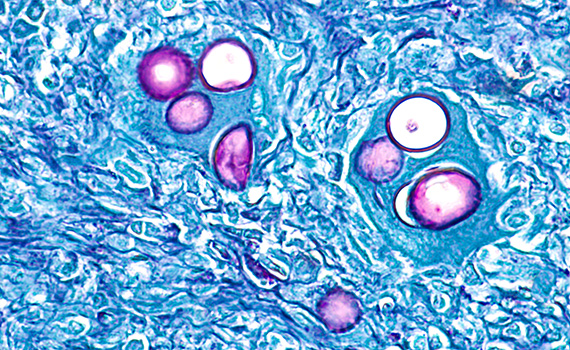

At the heart

of NE prevention is coccidiosis control, which requires proper coccidiosis

vaccination. Every chick must get a full dose of the vaccine at the hatchery. Bioshuttle

programs — administration of an in-feed anticoccidial at 3 weeks of age after birds

have been vaccinated — can be helpful, although there is a limited number of

products that can be used in NAE systems, he said.

Antibiotic alternatives have generated huge interest, and most NAE systems are using at least some of these products, which include probiotics, prebiotics, organic acids, essential oils, enzymes and mold inhibitors. However, Cummings said the NAE producers he’s worked with have yet to find an alternative product or combination of these products that consistently control NE.

Editor’s note: This video interview, podcast and news article were developed independently by the editors of Poultry Health Today. They are presented here solely for their news value. The opinions and recommendations presented are not necessarily shared by the editors of Poultry Health Today or the interviewee’s employer.

Posted on April 15, 2019

We’re glad you’re enjoying

We’re glad you’re enjoying