Experimental and applied approaches to control Salmonella in broiler processing

By Dr. Mark E. Berrang

USDA—Agricultural Research Service, Russell Research Center, Athens, GA

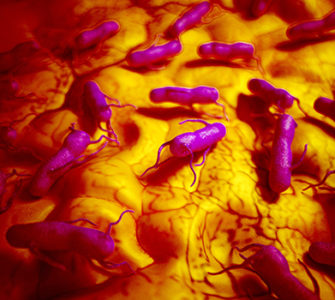

Control of Salmonella on poultry meat should ideally include efforts from the breeder farm to the fully processed and further processed product on through consumer education. In the U.S. regulatory scrutiny is often applied at the chill tank. Therefore, processing parameters are an important component in the effort to control Salmonella. At ARS-Russell Research Center, processing methodologies applied at commercial broiler plants have been examined to measure their effectiveness to decrease Salmonella prevalence.

Elevated pH in scald tank

A scald water additive (lime slurry) was used to increase the pH of scald water at a commercial processing plant from near neutral (approximately 7.0) to a more basic 9.89 in an attempt to lessen Salmonella contamination before feather removal. In both treated and control lines, scald temperature was between 50 and 55oC; carcass dwell time was 3 min 27 s. Carcasses subjected to the high pH scald were numerically but not significantly (P > 0.05) less likely to be contaminated with Salmonella than those treated by standard scald. After proceeding through commercial automated defeathering which increased Salmonella prevalence, a subsequent chlorine dip tank (10 s dwell time with close to 2 ppm active chlorine) was found to be ineffective to lessen Salmonella prevalence on carcasses previously treated with a high pH scald. It may be possible to effectively lessen Salmonella prevalence with a high pH scald tank but the cross contamination coincident with standard feather removal can be expected to largely “un-do” the benefit (Berrang et al., 2011a).

Chemical treatment during feather removal

Moderating increased microbial contamination during defeathering has been the goal of multiple research projects conducted by ARS at Russell Research Center. One such pro-ject was conducted in a commercial plant and involved application of chorine dioxide through existing plumbing in feather picking machines. Control carcasses picked with a standard water spray were collected first. Then, chlorine dioxide, generated on site, was sprayed through the feather picker drip line at 50 ppm. Carcasses subjected to standard control feather picking experienced a significant (P , 0.05) increase in Salmonella prevalence from 26% to 60%. Carcasses defeathered under a spray of 50 ppm chlorine dioxide did not have a co-incident increase in Salmonella contamination (Berrang et al., 2011b).

Brush and spray carcass washers

Commercial broiler processors employ various spray and brush washers on both the kill and evisceration lines. A study was conducted to examine the efficacy of multiple wash steps in a commercial broiler slaughter plant. Washers tested included: pre-scald brush washer, post-feather pick spray washer, inside/outside spray washer, subsequent brush washer and a final pre-chill spray washer. All washers were operated with chlorinated water (approximately 40 ppm). When examined individually, no single spray or brush washer had a significant affect on the prevalence of Salmonella. However, when applied in series as part of overall commercial processing, the result was a dramatic decrease in prevalence from approximately 80% pre-scald to 25% pre-chill (Berrang et al., 2009a).

Chemical processing aids

Finally, chemical processing aids are approved for use in commercial broiler pro-cessing to lessen microbial contamination. In 2006-2007 a yearlong study was conducted in 20 randomly selected large commercial broiler plants across the USA. This study represented eight integrated poultry companies operating in thirteen different states. Each plant used different combinations of processing aids. Carcasses were collected at re-hang and again from the same flock post-chill to determine Salmonella prevalence. Each plant was visited four times for a total of 800 broiler carcasses tested at each processing stage. We found 8 different types of processing aids (including none) being employed in on-line reprocessing. Some plants were also applying chlorine in washers and chill tanks. Salmonella prevalence ranged from 32 to 97% at re-hang and from 2 to 60% post-chill. Regardless of chlorine use or type of chemical aid, broiler processing significantly lessened Salmonella prevalence in all plants and all replications. We found that serotype of Salmonella detected had more to do with the incoming population than the antimicrobial chemicals used in pro-cessing (Berrang et al., 2009b).

Overall, broiler processing is very effective to lessen microbial contamination of car-casses; Salmonella prevalence is reliably lessened to a significant degree through modern processing techniques. Further research and ongoing optimization of processing parameters will help processors as they continue to improve the microbiological quality of poultry meat products.

References

Berrang, M. E., W. R. Windham and R. J. Meinersmann. 2011a. Campylobacter, Salmonella and E. coli on broiler carcasses subjected to a high pH scald and low pH post-pick chlorine dip. Poult. Sci. 90:896-900.

Berrang, M. E., R. J. Meinersmann, N. A. Cox and P. J. Fedorka-Cray. 2011b. Application of Chlorine Dioxide to Lessen Bacterial Contamination during Broiler Defeathering. J. Appl. Poult. Res. 20:33-39.

Berrang, M. E. and J. S. Bailey. 2009a. On-line brush and spray washers to lower numbers of Campylobacter and E. coli and presence of Salmonella on broiler carcasses during pro-cessing. J. Appl. Poult. Res. 18:74-78.

Berrang, M. E., J. S. Bailey, S. F. Altekruse, W. K. Shaw Jr., B. L. Patel, R. J. Meiners-mann and P. J. Fedorka-Cray. 2009b. Prevalence, serotype and antimicrobial resistance of Salmonella on broiler carcasses postpick and postchill in twenty U.S. processing plants. J. Food Prot. 72:1610-1615.

Article from The Poultry Informed Professional, Issue 123, March/April 2012. Published by the Department of Population Health, University of Georgia

Editor: Dr Stephen Collett, Associate Professor

Co-Editor: Dr Pedro Villegas, Professor

Department of Population Health

Posted on March 17, 2014